Tuesday

ABOUT SMELT

Sunday

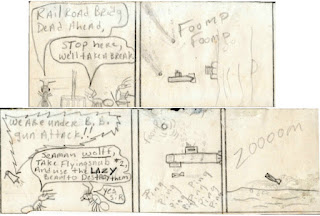

People have often asked how I got into cartooning? And what were

my first cartoons like. Well- here’s the answer. My very first cartoon strip.

It was early 1975 and while at my workbench in the electronics lab

at COC, I felt the urge to do some cartooning. I wanted to do cartoons with

sick violence, death and laughable characters. Of course, if an 11th

grader got caught doing such involving lots for people getting mowed down, even

in 1975 I’d have found myself in protracted counseling. I pictured myself in

old Dan Jacoby’s office looking at ink blots until I graduated. The answer was “ants”

you can kill as many as you want and no one cares! Since I’d been featuring

ants aboard my model rockets crashing to their doom- it was logical that his

ants and their ant world that exists among, but un-noticed by the humans, would

be the setting. Inspired by the old television series, “Voyage to the Bottom of

the Sea”, I began work on “Forage to the Bottom of the Sea” which featured not

only the ants, but my boyhood best friends Jim Brink and Ken Wolff.

Sketched within remarkably small frames and done

totally in pencil, the strips were crude and contained both off-color language

and sometimes humor that only the three of us could understand. The story was

that of a miniature submarine and its crew of ants that sailed from the creek

that ran behind my house in the farm-town of Freeland, Michigan to another

creek that ran near my old neighborhood on the east side of Saginaw, Michigan.

Interestingly, if you followed a map, in the 1970s it was indeed possible to connect the two

locations by way of water, so long as you can sail in depths of less than three

inches. Once back in my old neighborhood, the submarine ants engaged in a

fictional havoc imposed on Jim and Ken.

I knew nothing about cartooning and was doing the strips off-the-cuff as a pass-time to get my brain off of electronics (which by the way, I passed with an “A” in the 11th grader and qualified for “Advanced Electronics” in my senior year plus a job in that area after graduation- I was not a fan of electronics, but felt it may one day help me in aviation. The electronics training saved my ass in the cockpit more then once.) My ant characters were crudely illustrated and my penmanship and grammar were awful. Most of the jokes were inside stuff that only Jim and Ken could snicker at. I did, however, leave a few “easter eggs” as they call them today, for the guys. For example, the fish on the tree refers to Jim’s passion for fishing. Also "Brink" is the name of the ant who invades Jim Brink's home and then Jim feeds him to his fish- so he fed himself to the fish. Additionally, the serial number on the side of the “Flying Snub” 738278 was my serial number when I was in the Civil Air Patrol. Those give a clue as to how “inside” the humor was.

Yet cartooning was a great pastime. While most

folks sat and watched TV to pass the time- I sat and drew mindless cartoons.

The work quickly evolved and bettered. When I got to college a friend in the

dorm insisted that my cartoons go into the Avion student newspaper… and things

went nuts.

That, however, is another story.

Thursday

A HALF CENTURY AGO TODAY- SEPT.14TH, 1973

I’ve

published a version of this earlier, but today- September 14th, 2023

is a special day. At my age it’s not possible to remember what I was doing two

weeks ago today, but a half century ago today… well, those events are burned

into my soul. It was a Friday and it was a sharp turn for the better in my life.

Thus, I republish this as a celebration version of the moment when I moved to a

very nice place called Freeland, Michigan. It was a warm and friendly place

filled with good people and to this day, although I live far away, I still

consider it “home.”

As the

summer of 1973 drew to an end my parents were at the rough end of a long

decision process. Their oldest son, me, had just spent, or perhaps “wasted” is

a better term, the past three school years at an east side Saginaw, Michigan

Jr. High School called Webber. A century later that crap hole is nothing more

than a vacant lot and I, for one, could not be more pleased about that. At

Webber, nearly EVERY day presented a fight or a shake-down or some other

pointless commotion in the classroom. Very little learning went on other than

street savvy. By summer of 1973 I was scheduled to enter Saginaw High school where

things were actually worse than at that hell hole called Webber. Mom and Dad

were sure that their smart assed son would get knifed in a week at SHS. They

had just one real choice- move.

While our

house on Freeland’s Dawn Drive was still being finished, the school year

started. About a week and a half into the school year my folks finally arranged

for me to live at my aunt and uncle’s Freeland home on Church Street so I could

start Freeland High School. Mom and dad had tripled… I repeat… TRIPLED their

monthly house payment to move the family from Saginaw, Michigan’s Sheridan Park

to our new home in Freeland. But until our house on Dawn Drive was finished in

late October, I’d be commuting between Saginaw and Freeland every week.

Frankly, it was worth it to escape the Saginaw public school system.

My first day

at FHS began early on a Friday morning. In the pre-dawn, mom drove me from the

east side of Saginaw out to the farm town of Freeland. Due to overcrowding classes

for the high school were on half-day sessions beginning at 7am and finishing at

noon. Thus, by the time we arrived at the school things were well underway. We

stepped into the office where the ladies in the office staff were expecting us.

After some standard enrollment paperwork and their constructing of a schedule

for me, the new kid, I was quickly becoming a FHS student. The one problem was

that the Saginaw public school system was so far in the dumper that as a 10th

grader at FHS I would need to take a few 9th grade classes just to

catch up.

Soon mom and

I found ourselves in Principal Tom Vitito’s office as she finished my

enrollment paperwork. About the only kink in the process came when mom informed

Mr. Vitito that I’d be absent every Tuesday until further notice because I was

under subpoena as a witness in a murder trial. His eyes got big with this “My

God what kind of kid have I just enrolled?” look. Even after Mom assured him

that I was a witness for the prosecution, he still looked a bit worried. I

recall that he asked me what happened and I told him that I was not allowed to

talk about it until after the trial… that didn’t really help.

By the time

that the paperwork was done I’d missed first hour class and had to go on to my

second hour class- Michigan History. One of the ladies from the office led me

to the classroom, introduced me to the teacher, Mr. Judd Terwilliger, and I was

told to take a seat. Feeling like I had “New Kid” tattooed all over me I was

given my text book. Yet, what I was really concerned about was not the class,

but the up-coming change of classes. You see, at Webber, every new kid who came

into the school anytime after the first week got jumped and beaten up sometime

on their first day- usually in the hallway between classes- it was sort of an

indoctrination. Thus, I figured that the bell to end that class could very well

be my introduction to hallway pain.

The bell

rang.

My next

class was Drafting with Mr. Dan Craig and I had to walk nearly the length of

the school to get there. Yep, there I was walkin’ along with my antennas up

expecting to have to drop my books and fight at any moment. The worst part

would be that me, the five-foot seven-inch 135-pound scrawny new kid was gonna

lose any hallway fight. Surly, sometime today I was due for a pummeling that

would make a street hockey fight seem like a love fest.

Yet, nothing

happened!

In fact, as

I walked toward drafting class, there were three pretty girls standing by the

office and one of them actually smiled at me! I forgot all about getting beaten

up- I was completely enchanted. What kind of a place was this?

I had

“break” next in the “cafitorium” as I pronounced it, perhaps that was where I’d

get jumped. Nope… just kids, vending machines and more good lookin’ girls. It

had to be some sort of a ploy… they’d get me at dismissal and beat the snot out

of me outside of the school… right? Yet, there had not been a single fight all

day, and no one hustled me for my lunch money (which was in my shoe, just out

of habit) and kids actually carried books around. Plus- no cops… the whole day

went by and the police didn’t show up at the school for anything. Then at

dismissal, everyone simply went home. No one was hanging around in large groups

looking to nail the stragglers… everyone just… left.

I walked to

my aunt and uncle’s home to wait until my mom could come back out to Freeland

and pick me up and take me back to Sheridan Park for the weekend. There were

two nice bikes in the garage and my uncle had told me that I could use either

one whenever I wanted. Since I had about five hours to kill, I decided to take

one and ride out to the airport. It was a fine day as summer was still hanging

on and Tri City Airport was just a short bike ride away. I parked on Freeland Road

just off the end of Runway 5, sat in the grass watching the aircraft and

thinking about that girl in the hallway who’d smiled at me. Freeland High

School was polar opposite of what I had expected. Instead of getting chided and

beaten up by thugs, I’d been enchanted by an amazing blond!

The next day

I was back in my Sheridan Park neighborhood telling all of my friends about my

new school. No fights, I didn’t get jumped, no commotion in the classrooms, no

hustles for cash, plus the place was filled with good looking girls! My pals

were amazed, but convinced that I’d get jumped the next week.

That never

happened.

Freeland

High School was a safe clean place where learning actually could and did take

place, but it took several weeks for me to get used to it.

I was lucky

to escape SHS and to end up in FHS and to graduate with the class of 76.

However, I got the funny feeling that Mr. Vitito always kept an eye in my

direction, perhaps expecting another murder trial.

ANTLAB

Today, June 22, 2023 marks 50 years since the splashdown of the

Skylab 2 crew. As a 15-year-old space geek, and model rocket nut, I was totally revved up to do

something Skylab-like… and the answer was…

ANTLAB 1

Spaceflight is as much about inspiration as it is about

exploration and thus following the Skylab 2 mission, I was inspired to make my

own flying “workshop.” Taking one of my 1/200 scale AMT model Apollo Service

Modules and cracking it open I began to install balsa “habitation” equipment in

it.

My plan was to catch three little red ants from our patio,

stick them inside the thing and see how they would survive. I called the

project “Antlab 1.” Sure, I had to drill a small window into it so the critters

could look out and perhaps even get some air. Using a single edged razor blade,

I attempted to cut a small hatch in the side. A single slip of the hand and I

sliced two fingers! The blood would have panicked my mom so I used my Civil Air

Patrol first aid training and applied direct pressure with my paint rag until

the bleeding stopped. Lucky the paint on the rag disguised the blood and Mom

never knew how much I had hemorrhaged. Later in the day when mom finally saw

the wound, she decided that I should get an Xacto knife set as a belated

birthday gift; it was a little safer than the razor blade.

Once I had Antlab 1 fully configured I had to, of course,

ground test it. Using the un-mutilated fingers that I had left I caught three

ants and stuck their helpless little butts into the workshop. Waiting 24 hours

I opened it up and they crawled out; success! Now it was time for Antlab 1 to

be tested in flight.

Any rocket geek from the 1970s can tell you that the Apollo

SM from the AMT 1/200 model kit fit quite well into an Estes BT-20 flying model

rocket body tube. I just happened to have an Estes X-Ray rocket whose payload

section had separated and drifted away to God knows where. That X-Ray’s BT-20

booster tube would be adapted to boost Antlab 1. It did, however need to be

repainted black and white like a Saturn V first.

My scheme was to make a huge parachute out of a drycleaning

plastic bag that would be attached to the lab. The booster would be jettisoned

because, A: there was no room in the tube for a second parachute and B: I never

liked the X-Ray kit anyhow. The clear parachute would be so big that the Antlab

would practically hover in the sky and give the ants a lot of time to… crawl

around… in the sky. Frankly, if I had thought of it at the time I could have

applied to the United States FDA and gotten a huge federal grant for the project— it was that

strange.

On a calm summer morning in mid-July of 1973, Antlab 1

lifted off from 3324 Lexington Drive. The cut-down fins of the booster allowed

for a higher than expected flight and after a seven second coast the lab and

its chute ejected as planned.

Blossoming open, the lightweight parachute did exactly what I wanted and Antlab 1 seemed to simply hang in the sky. Ever so slowly it descended with its crew of three ants aboard. The mission would have been perfection if it had not been for the power lines behind our house. The following October, when we moved from that house, Antlab 1 was still hanging there on the upper-most wire. The mission lasted a lot longer than I had expected. I

t was a good thing that I gave the ants a window to look through.

Tuesday

I have just contracted to be aboard the luxury cruise vessel Le Bellot on their October 2 through 9 adventure. I'll be giving lectures and side-tables all about the Great Lakes. This is going to be FUN! For details visit https://www.gohagantravel.com/programs/cruising-the-great-lakes-2/

Wednesday

GO GET THE KID; THE BRUD MURDERS

Normally this blog is for fun and entertaining material. However, 50 years ago tonight, March 1, 1973, I became a key witness in a murder case. Part of trying to mute that demon a bit more is to write the story. Here it is... like it or not.

Copyright 2004 and 2023

Wes Oleszewski

All rights reserved-

this text is not for reproduction or publication in any form. Your viewing of

the text does not waive the above reservation.

NOTE: This is a completely true story. The name for Mr. “Brud” has been changed for

the purpose of this publication. The word “brud” is Polish and basically means

“filth.” Anyone wishing to find the individual’s real name can reference

mid-Michigan news items for the first days of March, 1973.

Go Get the Kid; The “Brud

Murder”

It was the first evening of March of

1973 and I was 15 years old and outdoors doing what most guys my age in

mid-Michigan would be doing… having a snowball fight with my buddies. There

were four of us, Jimmy Brink, Ken Wolff, Bill Hoffman and myself, all of whom

had grown up together in the tiny suburb of Saginaw known as Sheridan Park. We

had been out since the end of the school day gathering snow and flinging it at…

well… everything. For a while we had peppered passing cars, but then, fearing

that we may get into “trouble,” we switched to plastering one another.

For a short time, we had been in the

side yard of the Brud house, which was across the street from my house. Jim’s

dad, who was a detective sergeant on the Saginaw Police Department, had warned

us to stay away from Brud who was a convicted felon and child molester. Thus,

we soon moved up the block and continued horsing around. It was about then that

I saw a man coming out of the Brud house. He had an odd walk, like a gorilla

Bill quipped. So, we threw snowballs at him. He was about 200 feet away when we

first saw him and 260 feet away as he passed directly under the streetlight in

front of my house, so we never came close to hitting the guy. Yet, he never

looked up, he just kept walking until he passed out of sight up the street and

behind the houses.

Eventually we decided it was time to

call it a night and we all headed home. I was supposed to be watching my

younger brother Craig, who was nine and my sister Jeanine, who was 13, but they

were easily old enough to survive without me in the house. My mom and dad were

working at the Saginaw Civic Center where a Saginaw Gears hockey game was

taking place in the arena. Mom worked in the concession stands and dad was the

Zamboni driver for the hockey games. This was dad’s part-time gig; career-wise he

was a railroad engineer for the C&O. I came in through the front door and

my sister and brother were relaxing and watching TV; everything was quiet and

normal- for the moment.

About 45 minutes after I came home

there was a sharp knock at the front door. I went to answer the door and there

stood a uniformed Saginaw Police officer!

“OH CRAP!” I thought, “Someone

reported us for throwin’ snowballs at cars!”

“Are your parents’ home?” the officer

asked stoically.

“No,” I replied meekly, “they’re

workin’ down at the Civic Center.”

“How old are you?” He asked as he

looked past me toward my brother and sister.

“15.” I replied with a bit of a dry

swallow.

“Have you seen anything unusual

tonight?” the officer furthered his questioning.

“No.” I replied with a bit of

curiosity. If the cop was here to take me away for throwin’ snowballs at cars,

he was sure being indirect about it.

“Okay,” he ordered, “lock your doors

and don’t let anyone in until your parents get back.”

“Okay.” I agreed.

With that the police officer turned

and simply left. Over his shoulder I saw red and blue lights flashing

EVERYWHERE!

Dutifully closing and locking the

doors, I ran to my bedroom, which was at the front of the house, and peeked out

through the window. Police cars and fire department vehicles were everywhere

with their lights going and officers and detectives were going in and out of

the Brud house. What really got my attention was all of the detectives! I had

never seen so many, and more were arriving every second.

For a moment I pondered the

lightshow… then my creative AD/HD brain began to take over. What if someone

died in there? Or… what if someone was murdered! Suddenly, it went through me

like ice water… that guy we saw leaving that house! I ran to the phone and dialed

Jimmy’s number. He answered the phone, and I asked if he saw all of those cops?

“Yeah,” he said with a gasp, “two of

‘em are sittin’ here now talkin’ with my dad.”

“Jim!” I urged, “do you remember that

guy we saw leaving the Brud house?”

“Oh yeah,” he exclaimed in a whisper.

Jim put the phone down to his side

and I could hear him in the background calling out to his dad.

“Dad! Wes is on the phone, and he

just reminded me, there was this guy we saw leaving the Brud house tonight…”

In about three seconds Mr. Brink

snapped up the phone.

“Don’t go anywhere,” he ordered.

“don’t talk to anyone, I’m sending two officers over,” and he hung up!

I stood there in silence holding the

phone in my hand.

Holy Shit!

Mr. Brink, who I’d grown up with and

was like an uncle to me, only talked like that when things were really- really

bad! It seemed like only seconds passed, yet it must have been four or five

minutes and there was another sharp knock at the door. I dashed to the front

door and opening it I saw two detectives.

“Are you Wes?” the one in front

asked.

“Yeah.” I replied, still a little

stunned.

“Do you mind if we come in?”

“Heck no,” I replied in my best

Midwestern breeding, “come on in!”

We took seats at our family dinner

table and the detectives began to interview me. I described the man that I had

witnessed leaving the Brud home that night. To this day I can still describe

him from head to toe. He was a white man about six foot tall, no facial hair

and a fairly short haircut (by 1973 standards) a little longer than my

regulation Civil Air Patrol haircut. He had on a navy-blue bomber jacket with a

blue fur collar. It was un-zipped and under the jacket he had on a red

“lumberjack” shirt. Under that he had on a white T-shirt with a blue collar. He

was wearing dark brown corduroy pants with a wide brown leather belt that had a

round gold ring buckle. His shoes were light brown half-boots with a strap

across the front. And his walk was very distinctive- like a gorilla.

The murderer had been unlucky enough

to leave the scene of the crime in front of four boys ages 12, 13, 14 and 15. And

the 15-year-old, me, was an AD/HD who was also equipped with 20/15 vision. I

scoped him out and stored every detail. This was not for any other reason than

the fact that it’s the way my brain is hard-wired. People who are AD/HD may be

a pain it the ass to schoolteachers, but we make really good police witnesses.

Following my description, the

detectives began asking me a series of questions that many years later I would

learn were “test questions” to see just how good my memory of events happened to

be and what sort of personality I happened to have. That night, however, they

just seemed to be odd to me.

“What’d you have for breakfast

yesterday?” the lead dective asked.

“Peanut butter and strawberry jam on

toast.” I replied reflexively.

“How do you know that?”

“That’s what I have every day.”

“Do you eat lunch at school?”

“Yes.”

“What’d you have for lunch on

Monday?”

“A sloppy Joe, a bag of Doritos and a

chocolate milk.”

“How do you know that?”

“Because that’s what I have every day

except for Friday when they’re serving fish sandwiches, then I have one of

those. When I’m done with it, I wad-up the paper and stuff it into the pipe at

the end of the table.”

“Why do you do that?”

“Just for fun.”

“If I open your locker at school

tonight, what exactly will I find on the top shelf?”

“Absolutely nothing.”

“Why is that?”

“Because I never keep anything on

that shelf.”

Then the detectives switched

questioning a bit.

“What time did you come back indoors

tonight?”

“7:30.”

“How do you know that?”

“Because “Flipper” was just ending on

the TV and “I Dream of Jeannie” hadn’t started yet.”

Up until that point I actually had no

idea what had happened across the street, but I knew instinctively that it was

something bad. When I asked the detectives just what happened over there, I was

told flatly that “Two people were murdered there.”

Following that part of the interview

the detectives asked if I would be willing to go outside with them and show

them where I was at different times during the evening. I agreed and we headed

outdoors as soon as I put my jacket and boots on. Kensington Street, where the Brud

house was located, ran west to east and “T’ed” at my front yard and Lexington

Drive. We crossed Lexington and walked up to the Brud’s side yard.

“Were you guys playing here?” one of

the detectives asked as he pointed toward the footprints in the snow.

“Yep.” I replied.

“Are these your footprints?” He

asked.

“Yeah,” I responded pointing to my

own marks in the snow, “right there and here.”

“Are these the same boots you were

wearing?” the detective asked while pointing at my boots.

“Yeah.”

“Make a footprint right there,” the

detective directed me by shining the beam of his flashlight right next to one

of my boot-prints.

Doing exactly as I was directed, I

made a boot-print. The detectives closely examined the two prints and then

asked me to take them to where I was standing when I saw the man leaving the

house. We walked up Kensington to the front yard of the Smith’s home and again

I was directed to do the boot-print next to my own track. I showed the

detectives exactly where I was standing and told them that I actually saw the

man come out of the Brud house and explained where he walked. Next, we went to

the street in front of my house, and I showed the two detectives the route over

which the man had walked. Additionally, I showed them that he had passed

directly under the streetlight and that was how I was able to see so clearly

what he was wearing. Next the detectives and I went back inside my house and back

to my family’s kitchen table for a full repeat of my previous questioning.

While I was busy with the detectives,

another aspect to the story was taking place a few miles away at the Saginaw

Civic Center. The Saginaw Police Department’s officers did security at the

Civic Center and one of the officers sought out my dad.

“Walt,” the officer asked quietly,

“don’t you live in Sheridan Park?”

“Yeaht,” my dad replied in his

mid-Michigan accent.

“Do you know the Brud family?”

“They live right across the street,”

Dad responded.

“Well, you’d better get home,” the

officer directed sternly, “Bob Brud just came home and found his wife and

daughter murdered.”

My dad hustled to the arena’s

commissary where my mom was working.

“Get yer’ jacket,” he ordered, “we’re

goin’ home.”

Mom protested that she had a lot of

work to finish.

“Come on,” Dad insisted, “we’re goin’

right now!”

About then Civic Center manager and

our family friend Bill Fifer came in and told Mom not to worry about the work and

“Just go.” Of course, now Mom insisted on knowing what’s wrong. When Dad told

her, mom dropped her work and my parents headed home.

I cannot imagine the atmosphere in

that 1972 Ford LTD station wagon as my Mom and Dad raced home, because I was

not in the car with them. Yet anyone who is a parent can imagine what it was

like as my dad tooled that car through the streets only to reach Sheridan Park

and get stopped at the entrance to the subdivision by a police officer. After

explaining briefly who they were and where they lived and that their kids were

home alone the officer waved them through. My folks sped to our driveway. Then

they dashed to front door and burst into the living room only to find their

oldest son at the kitchen table being questioned by two detectives!

To say they were surprised would be

an understatement. Crapping a solid gold terd would be much close to the truth.

As my folks arrived the detectives

were just leaving- so mom and dad didn’t hear any of the questions and answers.

That was good because my mom was a perpetual gossip, and she would have been on

the phone the following day telling everyone every word of what had been said. Before

they left, the detectives warned me not to discuss what had happened with

anyone; friends, teachers, or parents and especially not the news media. I

would have my chance to tell everything to the prosecutor and in court, but

until then I was to not discuss the events that I had witnessed. Of course, as

soon as they departed, everyone wanted to hear everything… I told them nothing.

After the detectives departed, we

spent the night peeking out through our bedroom windows toward the drama across

the street. Most of my aunts, uncles and most of my cousins lived either in

Sheridan Park or within five miles, so we had people coming in and out all

night long. At about 11:00 that night, my kooky cousin Bobby came bursting in

through our back door carrying a loaded hunting rifle! He said he was there to

protect us while my dad was at work on the railroad. Later my cousin Stevie

dropped by and told us not to worry, because he had already ordered a pizza for

delivery to our house. The delivery guy got quite a surprise when he drove into

our normally peaceful Sheridan Park neighborhood only to find it packed with

police investigating a murder scene. Nothing like that had EVER happened in

Sheridan Park prior to this.

We stayed up through the night

watching the events through our bedroom windows. We saw the state police crime

lab arrive and later watched as camera flashes illuminated the windows of the Brud

house. None of us knew what was going on inside that house and none of us wanted

to know. In fact, it was a scene that would keep even the most hardened police

officer awake at night. There was one thing that everyone knew for sure and

that was the fact that there was a murderer on the loose; I knew for sure that

I had seen him leave the scene of the crime and I had just described him,

head-to-toe to the police. I felt somewhat comforted that the killer could not

describe me in the same manner.

Dawn broke and with it an early

spring fog settled over Sheridan Park. We watched as the coroner wheeled out

two stretchers with bodies wrapped in white sheets; one the size of an adult

and one the size of a child. The police cars eventually left one by one and

with them went everyone’s desire to watch through the windows. Mom said we did not

have to go to school that day and I crashed for a few hours of sleep.

When I woke up it was clear that the

story was huge in the news media. Local TV stations took turns standing in

front of the Brud house and reporting on the murders. I had the thought that I

could give them a scoop that would blow their doors off, but that thought was

tempered with the fact that the person I saw may not be the killer at all- he

could just be another witness; only the police would know for sure. The one

detail of my story that did get out was the part that my sister remembered me telling

the detectives were finishing my interview- it was the way that the guy walked;

“like a gorilla.” I was somewhat astonished at just how fast that little tidbit

got around. Apparently, Mom got that out of her and then was quite busy on the

gossip lines while I was sleeping. Of course, everyone wanted me to talk about

what caused the detectives to take such an interest in my story. Cousins

prodded as did aunts, uncles, and neighbors… I told them nothing.

My mom likes to tell the story of my

parents taking me to a small, local amusement park when I was four years old.

One of the park’s main attractions was a miniature train ride. Supposedly the

engineer of the train was carrying the payroll in a large canvas bag that he

proudly displayed before the trip began. The ride took passengers into the

local woods where eye-catching items had been set up. One of those was actually

a fake alligator; yeah, an alligator in mid-Michigan. Climax of the ride was a

staged train robbery with masked, old-west bad guys on horse-back who came out

of the woods firing six-shooters into the air, shouting, and circling the

train. The punchline was that the robbers made so much commotion, when the rode

off, they forgot the money. We boarded the train, which was no big thrill

considering that I had been climbing aboard real railroad engines since I

learned to walk. As we went through the woods out came the robbers! They

circled and shot their guns and hooted and hollered- then they left. As the bad

guys started to leave, I turned to my mom and said, “They forgot the money.” A

few seconds later the engineer laughingly held up the money bag and shouted,

Hey! You forgot somethin’…” and the rest of the train laughed. The point of

this little back-story being that I have always been a person who happens to notice

things that other people miss. This time, that little trait would pay off in a

very big way.

A few days after the murders we were

all at the Civic Center for public skating when one of the police officers came

up to my dad and said simply, “We got him,” then he added, “and he walks just

like Wes said.” That night on the local news we saw the police perp-walking

Robert Walton into the jail and people started calling our house saying that he

walked just way I said.

Once an arrest in the case had been made,

life in quiet Sheridan Park went back to normal. Yet about a month or so after

the murder, all four of us snowball throwers were ordered to come to the

courthouse to speak to the assistant district attorney. Once there we had some

fun playing the stairwell of the new courthouse building and one-by-one we were

asked to come into the office- I was the last one in. The other three guys were

in there for about 15 minutes each, not so with me.

Assistant prosecutor Ray Kasmeric, a

sharply dressed man with red hair and beard did the questioning and was aided

by a lady clerk. He asked me almost the exact questions that the detectives had

asked me on the night of the murder, and he got exactly the same answers. Then

he asked me to describe the man’s clothing again, and again, which I dutifully

did. Next, he briefed me on what court would be like. He made it very clear

that real court is nothing like what you see on TV. The defense attorney cannot

get up and strut in front of you and cannot get “in your face” and badger you.

He said that if the defense attorney tried something like that, “There are

things we can do to stop him.” He also made it clear that Walton would be in the

courtroom and will likely be looking right at me, but he is not allowed to say

anything. Then he told me something that would puzzle me for the next three

decades.

“When you are asked to describe the

clothing,” he instructed me, “you are to describe everything just as you did

today- except for the shoes. If you are asked about the shoes, you are to say

“I don’t recall.”

“But,” I mildly protested, “I do

recall the shoes, they were light brown half-boots with a strap across the

front.”

“And we’re telling you now,” he

replied firmly, “that you do not recall the shoes.”

It dawned on me that perhaps I had

not gotten the shoes right, even though to this day (more than a half century

later) I can close my eyes and see those shoes. Thus, I agreed that if asked

about the shoes I would say that I did not recall them.

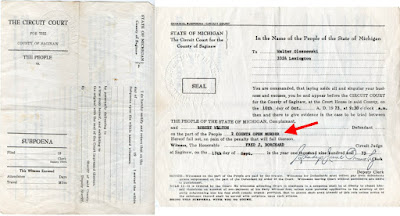

In mid-summer of 1973 all four of us

were called over to Jimmy Brink’s house. His dad was home for lunch and had

brought with him four subpoenas- one for each of us. Being a natural born smart

ass I asked if we could “dodge” the subpoenas like we see on TV.

“You can’t dodge a subpoena,” Mr.

Brink smirked a bit and then said, “I’ll show ya’ how you get served.” He

tossed my subpoena at my feet and said, “There… yer’ served.”

My subpoena was for the 17th

day of September, 1973 to appear in front of Judge Fred J. Borchard and the

defendant was Robert Walton on trial for “two counts of open murder.”

By September, my family was in the

process of moving from our beloved Sheridan Park to the tiny farm town of

Freeland. This was necessary to get me into a high school where I would not get

knifed considering that the school to which I had been headed was not a pillar

of education and a smart ass like me would have been sliced up within a week.

On the morning of my enrollment at Freeland High School I was sitting in the

principal’s office as my Mom made out my paperwork. Mr. Vittito, the principal,

knew that I had come from the east side of Saginaw, and was probably wondering

what sort of kid he was adding to his school’s population.

As we finished the paperwork, Mom

added, “Oh! By the way, he will be absent one day a week until further notice.”

“Why is that?” the principal raised

his eyebrows.

“He’s a witness in a murder trial,”

Mom stated matter-of-fact.

Vittito’s eyes got big! Then mom

quickly added that I was a witness for the prosecution, and I was not involved

in the actual murder. For the next two years while Mr. Vittito was principal,

he seemed to really keep an eye on me… just in case.

Mom drove me to court on the

appointed day and we were all told to wait in the hall. Meanwhile, our parents

were allowed to sit in the courtroom and watch the trial, but they were not

allowed to tell us what they saw and heard until after we had testified.

One-by-one the other three guys were called into the courtroom, testified and

left; I simply sat there- all day. Except for the fact that my day at the

courthouse was changed to Tuesdays, it was the same for the next week and the

next and the next and the next. Mom, however, was able to sit and watch the

trial- what she saw was shocking.

Walton, as it turned out, was the

homosexual lover of Bob Brud who had conspired to have his wife raped and

murdered. Brud’ four-year-old little daughter was also raped and murdered by

Walton, but his two-year-old son was untouched. This was an effort to draw

attention away from the fact that the murder was done by a homosexual.

Additionally, it came out that Brud was making pornographic home movies of his

wife and other men and selling them. Also, it came to light that Brud had

systematically lured little boys in Sheridan Park into his home, molested them

and then gave each one a model ship or airplane kit to keep them quiet. When

that information got out, suddenly mothers all through the subdivision realized

that their sons had brought home model kits that someone had given them. Confessions

led to a flurry of complaints filed with the police department. To make matters

worse, it was revealed that Brud and some fellow child molesters had

infiltrated the local chapter of Big Brothers and molested boys there. After

the trial, when I learned all of that I thought back to that day when Mr. Brink

called us all in and warned us about Brud. His blunt, firm warning probably saved

us from that monster.

As the trial went on and the weeks passed,

I thought that the prosecutors had forgotten about me. My Mom even asked if

they knew I was waiting and they said that they were fully aware that I was

there, waiting, and I would be called. Finally, as the prosecution was about to

close their case, Mom heard Brady Denton, the prosecutor, turn to Kasmeric and

say, “Go get the kid.”

As the courtroom door swung open, Mr.

Kasmeric stuck his head out and motioned to me to come in. Walking up the aisle

I could feel that every eye was on me. The bailiff walked me up to the witness

seat- it was black leather and over-stuffed. I gushed into it and was thankful

that it was too comfortable. There was no swearing in, Judge Borchard simply

asked me if I knew the difference between right and wrong and the truth and a

lie- I said that I did. There was a long pause as the prosecutor shuffled some

papers. Looking over at the defense’s table, there sat Walton. He had a yellow

legal pad in front of him with nothing written on it and three sharpened yellow

pencils neatly placed to the right of it. His eyes were locked on me, and he

appeared not to move or blink- he simply stared at me.

Denton started by asking for my full

name and my age- I answered. Then he asked what I was doing on the evening in

question. Soon he led into asking what I saw at the Brud house. Then he pointed

to a chalkboard that was standing at the front of the courtroom just to the

left of where I was seated. It had tape lines on it that drew a map of the area

where we had been playing that night. I was asked to go to the board and show

exactly where I was standing. Next, he asked for me to draw the path of travel

of the man that I had witnessed leaving the Brud house- I drew a dashed chalk

line. I was asked to show the location of the streetlight and draw a circle

showing the area that it illuminated. Then I was told to take my seat. As I sat

down, Walton was still staring at me. Immediately it struck me that he was the

bad guy, a murderer, and I was the good guy, on the side of the law and

justice. I thought, “Alright you bastard, you want a stare-down, you got it.”

And for the rest of the time, I looked directly into his eyes as I answered

questions from Denton.

Finally, Denton asked me to describe

Walton’s clothing. He asked about the jacket, the shirt, the belt, the pants-

but he didn’t ask about the shoes. Then he ended the prosecution’s questioning.

Judge Borchard asked if the defense had any questions for this witness?

Walton’s defense attorney was busy writing and never even looked up- “No your

honor,” he quipped. I was excused by the judge and told to step down. Walking

from the witness chair Walton kept his eyes locked on me and I stared right

back at that monster all the way past the defense table. Then I looked for my mom.

She was smiling proudly, but mom’s will do that.

Mom went back and watched the rest of

the trial after my testimony while I went back to a normal school schedule-

with Mr. Vittito watching me. On sentencing day mom and I went to the courtroom

together to see the murderer get his just deserts. Walton was convicted on both

counts of murder and sentenced to 30 years in the State Prison. Brud was never

indicted on any charge much to the dismay of the jury foreman, who I heard tell

the prosecutor point-blank, that they would have convicted Brud too.

Spin the clock ahead 31 years. I was

hanging out at Tri-City (now MBS International) Airport’s firehouse with a

friend of mine who was an airport fire fighter. In these days just after 9-11

security was really tight at MBS, but I got in through the gate that evening by

ringing the buzzer and when someone answered through the speaker asking who it

was I said Osama Bin Polack… and they let me in. I had brought in a radio-controlled

model boat that I had built for my buddy in order to swap it for some cool lake

freighter photos that he had. As we sat at the firehouse’s dinner table

haggling and I demonstrated how the boat’s controls functioned, one of the

airport police officers strolled in. The gray-haired officer stood there for a

while watching the model boat work and then he said,

“You don’t know a guy named Bob Brud,

do ya’?”

That question pushed my button in a

big way, I stood up, pointed my finger at the officer and half shouted,

“Bob Brud is a felon and a child molester,

he belongs in jail, and if I had the chance I’d put him there myself!”

“WHOA! WHOA!” the startled officer

exclaimed as he waved his hands out as if telling me to stay back. Then he

squinted and asked, “Did you used to live in Sheridan Park?”

“Yeah,” I snarled.

“Were you the…?” he began to ask as

he squinted more.

“No,” I growled, “I was one of the

ones he didn’t get.”

“Where’d you live?” he asked.

“3324 Lexington, cattycorner across

the street.”

His eyes got huge and he reached out

toward me.

“Yer’ the clothes kid!” he exclaimed

with a wide smile, “I did your interview that night!”

Meanwhile the airport firefighters

were a bit startled by my little outburst, but now the officer and I began to

laugh a bit. He told me that Walton was out of prison having served his full 30

years. I asked if I was at risk, and he told me that I was not. He had done

Walton’s release interview- it was his final assignment before he retired from

the Saginaw Police Department. Walton, he said, had totally lost his mind. The

killer has no memory at all of the murders or the trial and the only thing that

he asked was if the officers could have a traffic ticket taken off of his

record. A Canadian citizen, Walton was deported and driven into Canada by the

RCMP- he can never return to the United States.

Then, I asked the officer a question

that had been bugging me for more than three decades- why would they not allow

me to talk about the shoes?

“Oh! Oh!” the officer nearly jumped

from his seat, “Yer’ gonna love this! You are responsible for probably the most

overtime paid to Saginaw police officers in history!” he half joked.

As it turned out the circumstances of

the murders quickly led the detectives to Walton. When they arrested him, they

executed a search warrant on his home. In his bedroom closet they found every

stitch of the clothing that I had described- except the shoes.

“My partner and I laid those clothes

out on the guy’s bed and it was all there,” the retired detective said, “but

the shoes. We looked at one another and both said “We gotta find those f$%kin’

shoes!”

There was something incriminating about the shoes, so there began a city-wide search for the shoes. Trash cans,

sewers, dumpsters, mailboxes, pools- even the banks of the Saginaw River were

searched; nothing! Then they drove to Canada and with the RCMP questioned

Walton’s mother and searched her residence; nothing! The best that they could

figure was that he gave them to his mother immediately after the murders and

while driving back to Canada she tossed them out through the car window while

crossing the Blue Water Bridge and into the swift current of the St. Clair

River.

He also explained that I was the “bow

witness.” In other words, they had Walton all gift wrapped, and I was the bow

on top.

As the years went past since 1973

I’ve done a lot of jobs- some of which involved catching bad guys- in some

cases really bad guys. I’ve been asked by people, including police officers

that I have worked with, why it is that little five foot ten 176 pounds of me

seems to have little or no fear of the bad guys. The answer is simple, I have

stared into the eyes of the worst of them, and I helped put the bastard away. I

only wish we would have gotten Brud too. According to the Internet, he died in

2011. My hope is that he is currently rotating on a spit in hell.